ESG Report

Sustainably Advantaged Products

Our products and processes help make our customers – and the world – more sustainable

PPG has been an industry leader for nearly 140 years, providing its customers with inventive and trusted paints, coatings and specialty materials. And we continue to be a pioneer in developing industry leading technologies that solve the needs of our customers’ biggest challenges year after year.

In 2021, we introduced a new two-step methodology to identify sustainably advantaged products to support our ability to:

- Systematically validate basic sustainable attributes likely to impact PPG products today and in the future; and

- Assess the value contribution of PPG solution towards the UN Sustainable Development Goals. The assessment provides absolute data pertaining to a product's sustainability attributes, giving PPG credible, objective information to better understand and capture a product's quantifiable sustainability value.

New Methodology to Identify Sustainably Advantaged Products

Value Contribution to UN SDGs

- Food

- Water

- People & health

- Energy

- Infrastructure and cities

Systematic Review of Product Attributes

- Energy use reduction

- Emissions (air, water, soil) reduction

- Toxicity reduction

- Improved use of resources

- Extended useful lifetime

Meet our newest sustainable innovations

Whether our customers want to have a barrier of protection through antimicrobial paint, use our coatings to manufacture furniture, improve road transportation or set out to sea, we continue to provide innovative sustainable solutions that support various industries.

A few of our newest sustainably advantaged products are as follows.

Antibacterial and antiviral products provide an extra layer of protection

The COVID-19 pandemic raised many questions about how the built environment—residential and commercial—could and should do more to protect occupants from harmful pathogens, increasing awareness for the benefits of antibacterial and antiviral coatings.

In 2021, PPG launched two new interior coatings that provide a barrier from common viruses and bacteria. These paints are ideal for application in homes, hospitals, schools, nursing homes, restaurants, processing plants and retail establishments.

PPG COPPER ARMOR™

PPG COPPER ARMOR™ antimicrobial paint powered by Corning® Guardiant® technology is the first paint of its kind in the U.S. It uses naturallyoccurring copper to kill 99.9%* of bacteria and viruses within two hours of exposure, including the virus that causes COVID-19, MRSA, Staph, E. coli and others for up to five years.

PPG COPPER ARMOR™ antimicrobial paint powered by Corning® Guardiant® technology is the first paint of its kind in the U.S. It uses naturallyoccurring copper to kill 99.9%* of bacteria and viruses within two hours of exposure, including the virus that causes COVID-19, MRSA, Staph, E. coli and others for up to five years.

* Kills 99.9% of bacteria Staphylococcus aureus (Staph), Pseudomonas aeruginosa, Enterococcus faecium, Klebsiella pneumoniae, Acinetobacter baumanii, Enterobacter aerogenes, Methicillin-resistant Staphylococcus aureus (MRSA), Vancomycin-resistant enterococci (VRE), Escherichia Coli (E. coli), and Salmonella, and viruses Feline Calicivirus and SARS CoV-2 within 2 hours of exposure to paint surfaces.

COMEX® VINIMEX® TOTAL

COMEX® VINIMEX® TOTAL antiviral and antibacterial paint reduces 99% of bacteria and viruses responsible for the most common gastrointestinal and respiratory illnesses, including Influenza A H1N1 and SARS-CoV-2. The paint also kills E. coli, Staph, Salmonella and other pathogens. Comex Vinimex TOTAL Antiviral & Antibacterial paint's effectiveness at reducing bacteria and viruses on the dry paint surface within two hours has been verified by independent laboratories using globally recognized testing standards, such as ISO 21702.

COMEX® VINIMEX® TOTAL antiviral and antibacterial paint reduces 99% of bacteria and viruses responsible for the most common gastrointestinal and respiratory illnesses, including Influenza A H1N1 and SARS-CoV-2. The paint also kills E. coli, Staph, Salmonella and other pathogens. Comex Vinimex TOTAL Antiviral & Antibacterial paint's effectiveness at reducing bacteria and viruses on the dry paint surface within two hours has been verified by independent laboratories using globally recognized testing standards, such as ISO 21702.

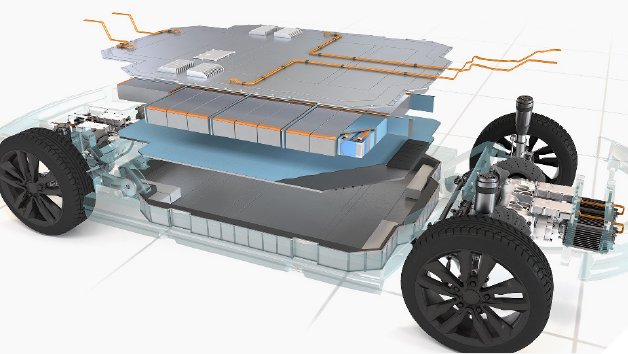

Safer battery coatings reduce risks and enable the electric vehicle revolution as consumer preferences change

Corrosion, thermal runaway events, arcing, and shorting events in electric vehicle (EV) battery packs can put battery operation and passenger safety at risk. EV and battery manufacturers need coating solutions that balance protection with performance.

PPG has developed a broad range of innovative coatings and specialty materials that advance vehicle manufacturers' electrification strategies and support improved battery safety, performance and lifetime, while simplifying manufacturing and reducing cost, all aligned with PPG and many of our customers’ sustainability efforts.

For example, PPG is working on several innovative coatings to protect EV batteries from fire, dielectrically isolate high voltage systems and manage thermal events.

PPG CORACHAR™ SE 4000 Battery Fire Protection material

PPG CORACHAR™ SE 4000 Battery Fire Protection material, protects the battery pack components if a thermal event occurs by compartmentalizing the event for a period of time to allow safe egress and response, improving safety for passengers and first responders. These solutions can be efficiently applied in mass production and are suitable for various battery electric vehicle applications.

PPG ENVIROCRON™ Extreme Protection Thermally Conductive Powder Coatings

PPG ENVIROCRON™ Extreme Protection Thermally Conductive Powder Coatings bring dielectric protection and thermal conductivity together into a single multipurpose coating. PPG's propriety technology enhances battery thermal management system (BTMS) efficiency while providing exceptional electrical isolation of battery cells and BTMS components, mitigating arcing and shorting events altogether while improving battery performance and passenger convenience and safety.

These 100% solids, solvent free coatings systems are designed to minimize emissions and minimize waste.

Innovation Exploration – Mobility Solutions

Electric vehicles and changing trends in mobility provide a great opportunity for PPG to grow organically through our innovative solutions addressing battery assembly challenges. Get a closer look at our innovative technologies and the partnerships we've built in order to expand our reach in this growing market.

Watch VideoPPG EV Battery Pack Materials Solutions

Vehicle and battery OEMs can rely on and other #PPGSmartLayers to enhance the performance, durability, safety and cost of EV battery packs. Corabond structural adhesives are ideally suited for fixing of cells and modules into packs as well as providing outstanding structural reinforcement and impact resistance.

Watch VideoPavement solutions help make traffic safer

For safer rides on the road, our Traffic Solutions business developed THERMODROP®, a pelletized thermoplastic road marking paint that is environmentally cleaner to apply and provides better striping production efficiency compared to other products currently used in the industry.

This product's sustainability is made possible through the use of beads that are made of 100% recycled glass. The ThermoDrop coating offers quantifiable environmental benefits to our customers based on its cleanliness when transferred to kettles and handliners used to apply the product. Further, this product's safety and health risks are minimal due to minimal dusting during application.

The ThermoDrop product makes it possible for our customers to reduce their environmental impact via an estimated 35-45% reduction in fuel costs, 30- 40% reduction in labor costs, and 30% increase in productivity and profitability.

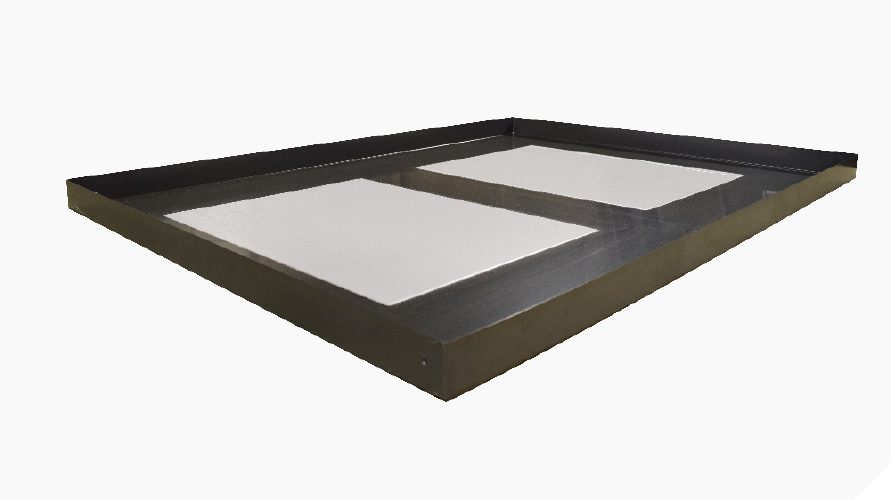

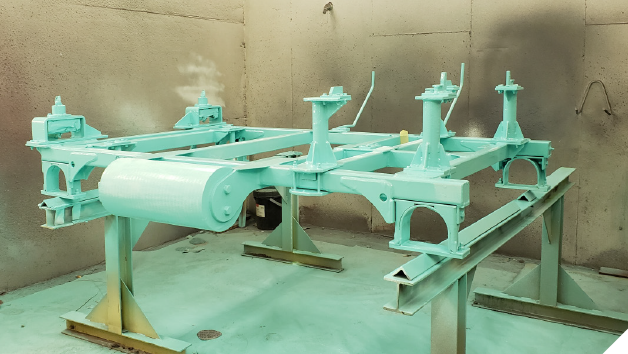

LINEGUARD™ Coatings help industrial paint lines improve water conservation and waste generated

Automotive assembly plants and other industrial equipment paint lines need to maintain paint equipment to ensure quality of coatings application and a safe operating environment. These maintenance activities can be both time- and resource-intensive, as removal of applied coatings is difficult to do efficiently and often requires large quantities of water using high pressure cleaning equipment.

Listening to our customers and knowing the challenges of ongoing maintenance, PPG developed and introduced PPG LineGuard coatings and application services—a comprehensive line of technologies that are proven to resist adhesion to and buildup of paint. These products were created specifically to help paint lines dramatically reduce the time, cost, risk, excessive water use and waste associated with cleaning and maintaining equipment.

LineGuard coatings:

- Include non-stick properties, so they don’t require high water pressure for cleaning, reducing employee exposure to hazards of using high pressure tools; and

- Are suited for a wide variety of paint shop equipment, from vehicle carriers to floor grids.

Through the use of these coatings, customers can see up to a 75% maximum reduction of cleaning cycles, bringing significant savings in labor and materials, energy, water and waste removal.

COMEX® paint made from recycled materials saves 270,000+ tires from landfills

PPG's Comex business is contributing to the circular economy through its new TOP recycled tire paint for DIY and professional painters. Intended for application on roofs, the product provides thermal insulation and waterproofing, resulting in emissions reduction through energy savings.

Ergonomic spraying solutions help reduce stress

Our HOMAX® TEX>>PRO™ product is a breakthrough sprayer system that reduces the weight of the tool by 60% – roughly 15 pounds – compared to traditional hopper spray guns.

When fully loaded, the 10-pound Homax Tex>>Pro Texture System eliminates the need to use bulk materials and increase ease of use and convenience for professional contractors and do-it-yourself customers, compared to heavy, traditional hopper spray guns. Last year, because of its ergonomic and innovative design, Homax Tex>>Pro sprayer system won PPG’s internal Ergo Cup competition.

GREENGUARD® certified adhesive technology provides initial grip and long-term strength

Builders, contractors and painters can further reduce their environmental impact with our newest adhesive innovation, LIQUID NAILS® FUZE*IT MAX™ product by PPG. Delivering the strongest bond from start to finish, the product offers five times the initial grab and long-term hold of previous products and bonds nearly any material in all weather conditions. Liquid Nails Fuze*It Max adhesive offers easy application and can be applied in temperatures ranging from 0 up to 140 degrees Fahrenheit. The adhesive's low volatile organic compound (VOC) formulation enables its Greenguard Gold certification to help contractors 270,000 attain points under current green building programs.

Architectural solutions help address infrastructure sustainability challenges

Architects have long relied on traditional fluoroethylene vinyl ether (FEVE) powder coatings to protect and visually enhance architectural extrusions and sheet metals. The low transfer efficiency rates in these coatings have forced many to use more product, leading to higher cost.

In addition, standard FEVE powder systems are onecoat solutions in the market with no primer. Corrosion resistance of these systems is highly dependent on metal and surface preparation. CORAFLON® Platinum is formulated to improve adhesion to metal and corrosion resistance as a one-coat solution, leading to significantly improved corrosion protection for all installations, including those in highly corrosive environments, such as seacoast and industrial. This performance reduces metal degradation and the need for frequent reapplication, which is a source of waste and environmental impact.

We introduced the new PPG Coraflon Platinum FEVE powder coatings designed to address challenges and reduce waste and environmental pollutants.

Coraflon Platinum coating features:

- Significantly high transfer efficiency rates, which are more than 20% higher than standard FEVE powders;

- Improved corrosion resistance backed by years of third-party testing; and

- Designs that stand up to strict environmental Standards.

In addition, the product is specifically formulated without:

- Triglycidyl isocyanurate (TGIC)

- Perfluorooctanoic acid (PFOA)

- Fluorosurfactants

- Volatile organic compounds (VOCs)

- Hazardous air pollutants (HAPs)

- Living Building Challenge (LBC) Red List substances

- REACH compliant – Substance of Very High Concern

- (SVHCs)

Unique hybrid coating for metal furniture adds styling and sustainability benefits

Traditional liquid and solvent-based coatings for metal office furniture may contain harmful substances and VOC emissions. They also have a low transfer efficiency rate, meaning it may require more passes and more product to achieve a complete coating. Additionally, over-sprayed coatings traditionally cannot be captured and reused, therefore creating waste.

Launched in April 2021, PPG ERGOLUXE™ and ErgoLuxe Eco powder coatings provide a protective and luxurious finish for office furniture. While both offer the sustainable benefits associated with powder, ErgoLuxe Eco powders offers a unique formulation containing up to 14% post-industrial recycled plastic (rPET). Customers have relied on our sustainable rPET technology for years, with more than 6 million pounds used since its introduction in 2017.

ErgoLuxe Eco coatings are designed to protect and beautify office furniture and are available in a wide range of colors, textures and metallics. Environmental benefits include lower VOC emissions when compared to traditional liquid coatings, higher first pass transfer efficiency rates up to 85% and overspray reclaim and reuse.